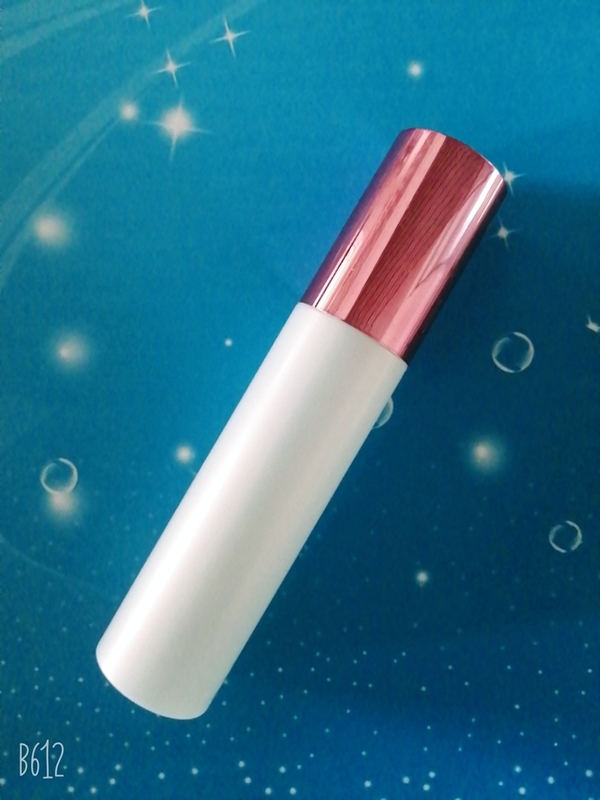

Screen Printing Cosmetic Spray Bottle 80ml For Moisture Cleanser ODM

Product Details:

| Place of Origin: | DONGGUAN |

| Brand Name: | SANRONG |

| Certification: | ISO9001:2015 |

| Model Number: | SAC080-BB |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10,000PCS |

|---|---|

| Price: | depended on the final quantity |

| Packaging Details: | normal packaging with individual polybag |

| Delivery Time: | 30-35days |

| Payment Terms: | T/T |

| Supply Ability: | 250,000pcs |

|

Detail Information |

|||

| Industrial Use: | Cosmetic | Usage: | Cosmetic Personal Care Packaging |

|---|---|---|---|

| Surface Handling: | Screen Printing | Keyword: | Plastic Cosmetic Bottles |

| Logo: | Custom Logo | Brand: | SANRONG |

| Highlight: | Screen Printing Cosmetic Spray Bottle,80ml Cosmetic Spray Bottle,ODM Spray Bottle Cosmetic |

||

Product Description

Plastic Cosmetic Bottles Used For Moisture Cleanser With Mist Sprayer

Features

1. Bamboo packaging is Eco-friendly, durable, and not deformation

2. Professional manufacturer of cosmetic Bottles, cream jar, lotion bottle and so on.

3. Our goods are excellent in quality and reasonable in price.

4. Our bamboo products are 100% purely hand-made.

5. Different shape for your choice.

6. Logo: Available.

7. Customer’s design are acceptable

|

Specification |

|

| Material | PET plastic |

| Capcity | 80ml |

| Color | customized color is available |

| Sample Supply | Free |

| Transport | Fedex/DHL/EMS/UPS/TNT/By sea/By air etc. |

| MOQ | 10000PCS |

| Delivery time | Samples 7days, mass production 30-40days. Depends on order quantity and actual situation. |

| Payment | T/T 40% deposit, balance before shipment. |

| Remarks: | We have professional service, If you have any questions, please contact me. |

![]()

Dongguan Sanrong Daily Chemical Container Co., Ltd, established in 1998, is exclusively invested by Sanrong Group in mainland China. The corporation specializes in the manufacturing of PET package containers, widely used in cosmetic, shampoo, lotion, food, health care and so on.

The corporation is well equipped with advanced technology, production & testing facility in order to serve the top quality. The process technology are designing, opening the mould, injecting, blowing, multi-color printing, labelling and gilding. The capacities of produced bottles are from 10ml-5000ml with the maximum yield of 8 million per month to meet the requirement for different capacity and variety of sizes.

The corporation employs some well-trained engineer with more experience. They devote themselves to researching & developing the top quality products. Operate under a total quality management system, the corporation has passed the certificate of IS09001:2008 in 2014. Our mission statement is to offer best customer service, top quality products and the maintenance of corporation reputation.